Basically will in a lathe a round sheet of metal (blank), be spun over a form (mandrel). This will be done successively, with the help of a handhold spinning tool. The movements of the tool, has to be smooth and even, otherwise could the material crack or be deformated. At more advanced spinning, will the form only give minor support. Often has the spinner to work in several steps, then with different tools.

In the image are A the lathes headstock, B is a mandrel (form to spin on). C is a follower. This will press the round sheet (blank) firmly, between the mandrel and the tailstock. D is the shaft of the tailstock. Number 1-5 shows different stages, when the round sheet changes into an item.

afTRYCK

The following comes from afTRYCK, which you can download HERE. There are only parts visible here, without any real links between them.

HISTORY 2

More reliable proof comes from the Roman Empire. The helmets carried by the legioners were to some extent made by spinning. This at least when we talk of such made of brass. Helmets of steel should by some information, been to hard to work. The quality of aviable materials may also be something to consider. Metal spinning demands sheets of good standard. I presume that most items of this sort were battered with a hammer. Items as helmets were though made in large numbers. As maybe the only alternative, must spinning have been a radical step forward.

Well it`s known that the Romans used waterpower to run other kinds of machinery. In theory so could the streaming water had been the provider for work of heavier spinning. But if this was anytime a reality, is a totaly different question.

HISTORY 9

When we now take a look into the industrial days, so will we meet a flat-belt driven lathe, that get its power from above. This was a product of the 1800-s but was still hanging around a good way into the next century. The point of using one central power-supplier, feeding several machines, was most of all economical.

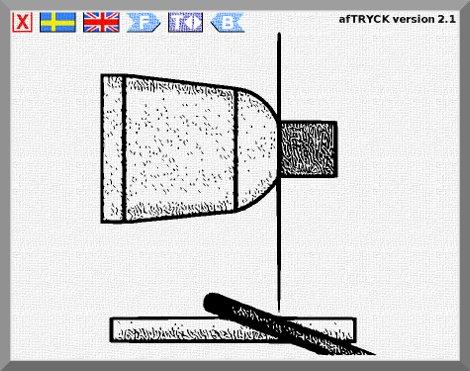

The picture shows a headstock with different sized pulleys. From one of them is a flat-belt seeking its way upwards to the transmission.

SPINNING 4

When a blank (the work-piece) are located at its position (between the mandrel and a follower) will it often be somewhat of-centre. This is corrected by loosing somewhat on the tailstocks wheel, and then with a tool pushing the blank into a centered position. This tool can be a piece of steelrod or similar.

The work-piece has in most cases to be lubricated. This to reduce the friction that occures between the tool and the blank. A good lubricator should be so stiff that it not splashing around. A smaller amount are often better then the opposite. It shall also be easy to remove afterwards.

SPINNING 10

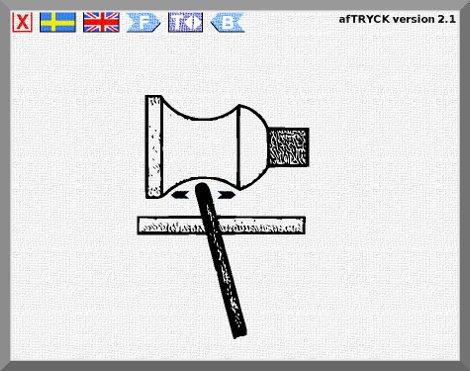

If you can´t make it in one step, do it in twice (or more). Here has the part been pre-spun once, and then placed over a second mandrel (dividable or only partly supporting), to be worked once more.

Spinning with only partly support of a form (mandrel) can be seen as "spinning in the air".

EQUIPMENT 1

The metal spinning lathe, can be described as more of a sturdy wooden-lathe, then an ordinary metal (capstan) one. Special features are the robust tailstock and the toolrest with holes (for a supporting steelpin).

The picture shows a lathe with:

1- Headstock/Transmission housing

2- Mandrel(form you spin on)

3- Follower(Holdes the blank between the mandrel and the

tailstock)

4- Tailstock

5- Toolrest/Toolpost

EQUIPMENT 10

To fold back a rim and for example make it rounded (bead), will a special tool be used. These can be fixed, but also in form of a rotating role. The picture shows only the tip of the tools. In reality has they a long wooden handle, similar to the spinning tool.

You can though fold a rim with just a piece of wood or a bit of flat metal. But the quality of the work will in the long run, probably be better with real equipment.

SUPPLEMENT 1

Different shapes makes the work more or less easy. If you have high demands on looks and measures, so is a cylinder somewhat harder then a taper. This because a straight surface unveils even smaller misstakes. The taper are good in such a way that it gives more and more support, during work.

The item down-below are a half-deep dish/plate. These items are normaly only spun a short distance and has also good support from the mandrel and follower. But the diameter of the blanks can be quite big, so folding a rim on a large item like this can be heavy.

WORDLIST ENGLISH-SWEDISH

Acid flux - Lödsyra

Adjustment - Inställning

Alloy - Legering

Aluminium sheet - Aluminiumplåt

Anneal - Glödga

Argentan - Nysilver

Artisan - Hantverkare

Axelshaft - Drivaxel

Ball bearing - Kullager

Bearing housing - Lagerhus

Bearing play - Lagerspel

Base metal - Oädel metall

Bevel - Fas

Blunt edge - Slö egg

Border - Kant

Brass sheet - Mässingsplåt

Brazing - Slaglödning

Burr - Grad, Skägg

Calipers - Krumcirkel

Candlestick - Ljusstake

Centralizer - Centreringsverktyg

Centre - Dubb

Centre distance - Dubbavstånd

Centre height above bed - Dubbhöjd över prisma

Clamp - Klämma

Clamping plate - Planskiva

Coarce thread - Grovgänga

Concave - Konkav

Convex - Konvex

Copper sheet - Kopparplåt

Craftsman - Hantverkare

Cup - Bägare

Curve shears - Rondellsax

Deburring - Avgradning

Dimension - Mått

Easy to work - Lättbearbetad

Edge(on sharp tool) - Egg

Edge - Kant

Female thread - Muttergänga

Flange - Fläns

Flaw - (Metall)blåsa

Follower - Försättare

Handle - Handtag

Hand wrought - Handsmidd

Hardening - Härdning

Hard to work - Svårbearbetad

Jaw - Chuck

Joint - Fog

Jug - Kanna

Lap - Fog

Lapjoint - Falsfog

Lathe - Svarv

Linear measure - Längdmått

Mandrel - Patron

Metal circular blank - Rondell

Metal spinner - Trycksvarvare, Metalltryckare

Metal spinning - Trycksvarvning, Metalltryckning

Nickle clad sheet - Förnicklad plåt

Nipple for greasegun - Smörjnippel

Of even thickness - Jämntjock

Ovality - Orundhet

Pewter sheet - Tennplåt

Play - Spel

Pitch of centres - Dubbhöjd

Precious metall - Ädelmetall

Pulley - Remskiva

Right hand thread - Högergänga

Rivet - Nit

Rolling mill - Plåtvalsverk

R.P.M.(Rotations per minute) - Varv per minut

Seam - Söm

Shavings - (Metall)spån

Smooth grinding - Blankpolering

Solder - Lod, Lödtråd

Soldered seam - Lödfog

Soldering wire - Lödtråd

Spelter solder - Mjuklod

Spinning - Tryckning

Spinning tool - Tryckstål

Steel sheet - Stålplåt

Sweated together - Mjuklödd

Tailstock - Dubbdocka

Tailstock live centre - Roterande dubb

Taper - Kona

The lead of the thread - Gängstigning

Thread - Gänga

To batter - Driva

To beat out bosses - Hammra ut bucklor

To clamp - Spänna fast

To cold work - Kallbearbeta

To cut off - Kapa av

To flat polish - Mattpolera

To put together - Montera (ihop)

To soft anneal - Mjukglödga

To solder - Löda

To tighten - Dra fast

Toolpost - Anhåll

Toolrest - Anhåll

Warped - Skev

Waste metal - Metallskrot

![]()

METAL SPINNING 1909 AND 1912

By clicking the link HERE, can you study a section of the book METAL SPINNING PRINCIPLES OF THE ART, AND TOOLS AND METHODS USED (second edition, 1912). The text is probably written 1909, this by C. Tuells. Also available is a chapter from another book with the short but accurate title METAL SPINNING (by Fred D. Crawshaw). This published in 1909, a good year for this type of reading, apparently. Translations is to be found in the Swedish section.

©Jan Lindström 2015-2025

BACK

BACK